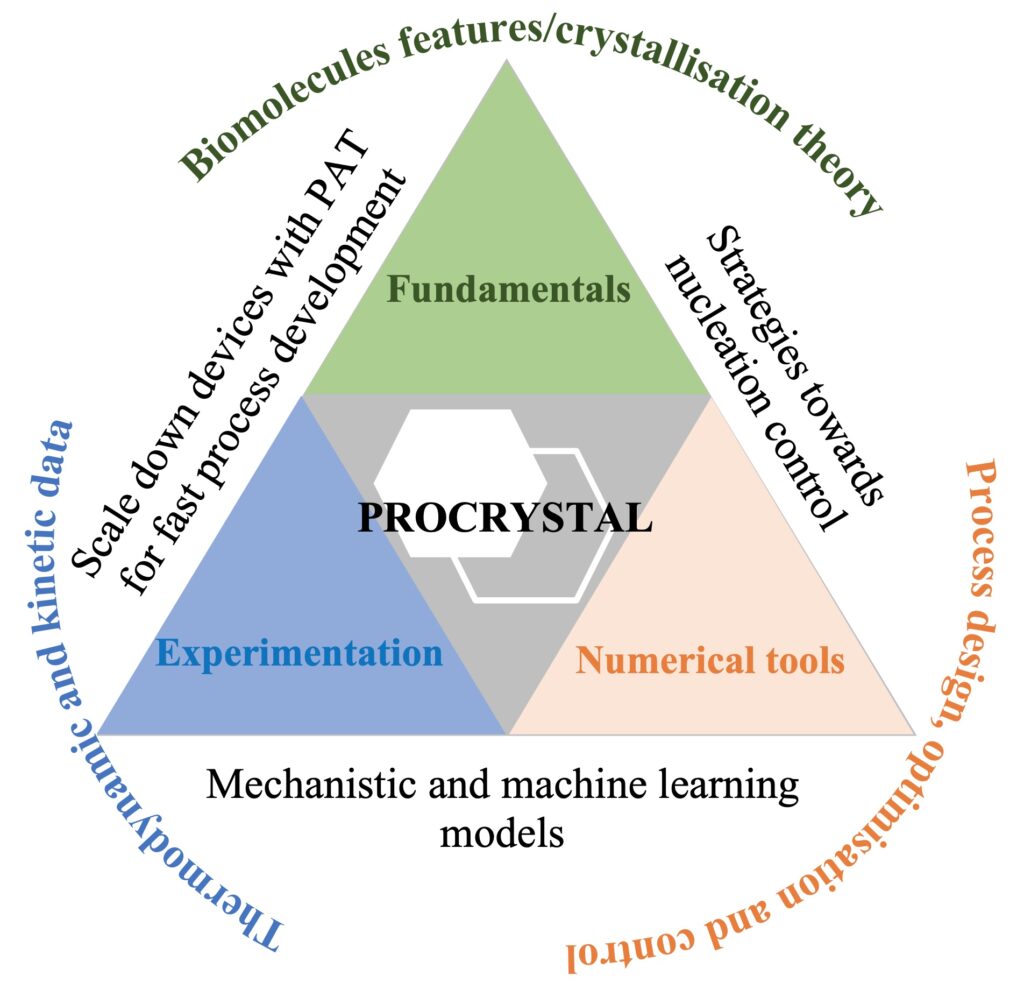

The training program "Crystallisation towards efficient and sustainable biomanufacturing" (PROCRYSTAL) vision is that of crystallisation as a simple, sustainable, cost-efficient and scalable alternative to current techniques and formulations.

Downstream processing (DSP) of biopharmaceuticals is dominated by chromatographic steps which suffer from low throughput, poor scalability and elevated energy consumption, as well as high equipment and materials costs. To this is added the low stability and high degradability of liquid formulations. The training program “Crystallisation towards efficient and sustainable biomanufacturing” (PROCRYSTAL) vision is that of crystallisation as a simple, sustainable, cost-efficient and scalable alternative to current DSP techniques and liquid formulations, once it allows to separate, purify and stabilise in a single step. Nevertheless, integrated training to exploit biocrystallisation full potential is currently not available, only fragmented research activities. Within this training program, 15 Doctoral candidates (DCs) are expected to go beyond current practise to respond to the near future biopharma manufacturing needs. And only possible leveraged by the expertise conveyed in this consortium on biomolecules crystallisation, biochemistry, chemical and process engineering as well as advanced modelling. The PROCRYSTAL training program for the DCs has been framed with special attention to fundamental understanding of the underlying phenomena, from the molecular scale to process scale, and advanced experimental and modelling techniques specific to crystallisation technology. The DCs will acquire a wide range of subject specific and general transferable skills, in an interdisciplinary and inter-sectoral environment and by multinational collaboration which enhances the early-career DCs long term employability and competitiveness.

DESCRIPTION

PROCRYSTAL is an innovative multidisciplinary and intersectoral training programme that will support and train the next generation of highly skilled engineers and scientists, with a holistic view from lab bench-to-shop floor and a creative mindset to resolve the current and future challenges in the dynamic biomanufacturing industry to boost EU’s capabilities. 15 DCs will be trained with an integrated training approach to solve current challenges in biopharmaceuticals DSP. The DCs will acquire fundamental understanding of the underlying phenomena, from the molecular scale to process scale, and gain experience of both advanced experimental and modelling techniques specific to crystallisation technology.

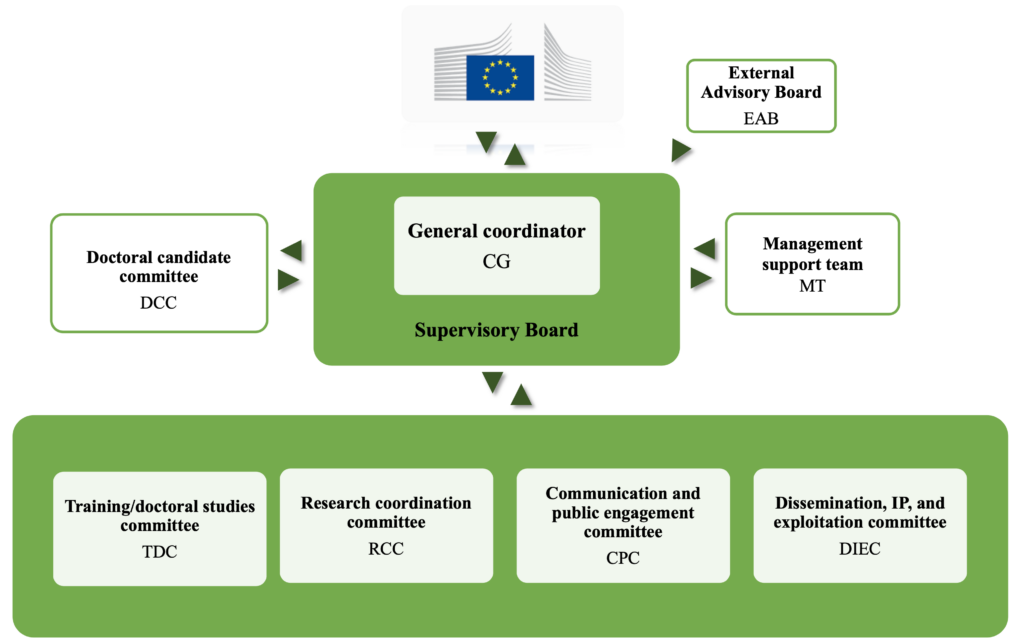

ORGANIZATION

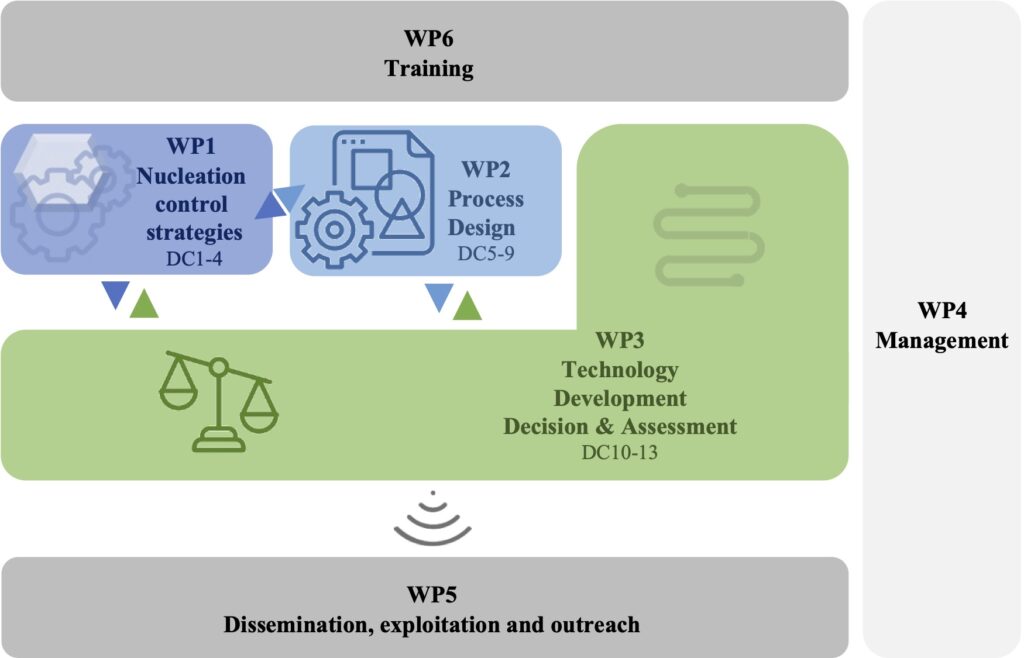

The project contains 6 work packages (WPs), three of which are research based as illustrated in the scheme. The approach of PROCRYSTAL revolves around close integration of innovative biochemistry, biotechnology, crystallisation, process design and modelling. All the DCs will experience the complete path from molecules behaviour to complete process design and evaluation.

The implementation is achieved via 3 highly interactive science and technology WPs. Critical insights into biomolecules nucleation control (WP1) and process design (WP2) are provided thought experimentation in scaled-down technologies with advanced PAT tools (WP3), assisted by modelling.

Management structure of the PROCRYSTAL network.